How Predictive Analytics Optimizes Maintenance

Imagine a world where your facility whispers warnings before problems arise. A leaky pipe sighs before it bursts, an overworked HVAC system groans before it sputters out. This isn’t science fiction; it’s the power of predictive analytics in facility maintenance.

What is Predictive Analytics in Facility Management?

Traditionally, facility maintenance relied on reactive measures – fixing things when they break. Predictive analytics flips the script. By harnessing the power of data, it allows you to anticipate equipment failure and address issues before they snowball into costly disruptions.

Here’s how it works:

- Sensor Network: Sensors are deployed throughout your facility, collecting real-time data on equipment performance, vibration, temperature, and other parameters.

- Data Gathering & Analysis: This data is fed into a central system, where advanced algorithms analyze trends and identify anomalies.

- Predictive Modeling: Based on the analysis, the system predicts when equipment is likely to fail.

The future of facility management isn't waiting for problems to happen, it's about harnessing data to predict and prevent them. Predictive analytics is the key to maximizing uptime, minimizing costs, and creating a future-proofed facility.

The Benefits of Predictive Maintenance

Predictive analytics offers a plethora of benefits for facility managers:

- Reduced Downtime: By proactively addressing potential problems, you can prevent equipment failures and minimize disruptions to your operations.

- Cost Savings: Early intervention is key to preventing costly repairs and replacements. Predictive maintenance optimizes maintenance spend by focusing resources where they’re truly needed.

- Extended Equipment Lifespan: Catching issues early allows you to take corrective measures and extend the lifespan of your valuable equipment.

- Enhanced Occupant Comfort & Safety: Predictive analytics ensures optimal environmental conditions (temperature, humidity) and can even identify potential security risks.

- Data-Driven Decisions: Move beyond guesswork. Predictive analytics empowers you to make informed decisions based on real-time data insights.

Putting Predictive Analytics into Action

Implementing predictive analytics doesn’t require a complete facility overhaul. Here’s a roadmap to get you started:

- Identify Critical Equipment: Focus on equipment essential for your operations and those historically prone to breakdowns.

- Invest in Sensor Technology: Choose sensors that capture relevant data points for your prioritized equipment.

- Embrace Data Integration: Ensure your facility management system can seamlessly integrate with the sensor network and analytics platform.

- Develop a Response Plan: Establish protocols for addressing potential issues flagged by the predictive analytics system.

Conclusion

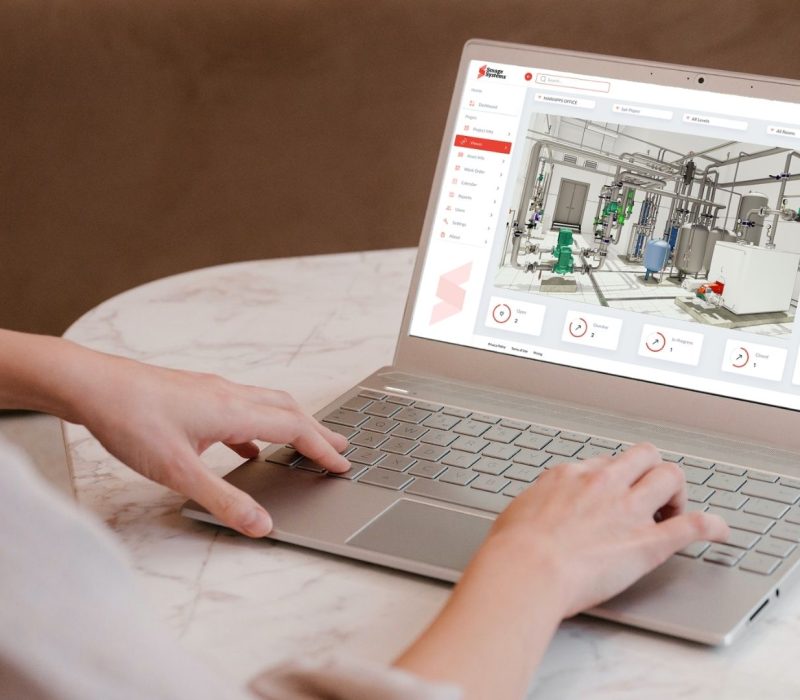

The traditional reactive approach to facility maintenance is a thing of the past. Smage Systems, a pioneering startup, is leading the charge with a revolutionary SaaS FM platform that leverages the power of BIM (Building Information Modeling), AI (Artificial Intelligence), and IoT (Internet of Things) to unlock the true potential of predictive analytics.

Imagine a future where your facility becomes a self-aware entity, constantly communicating its health and needs. With Smage’s AI-powered platform, this vision becomes reality. By integrating seamlessly with your existing BIM models and sensor network, Smage provides real-time insights and predictive capabilities, empowering you to take control of your facility’s maintenance destiny.

**Don’t wait for the next breakdown to disrupt your operations. Embrace the future of facility management. **

Have questions or want to learn more about how Smage Systems can benefit your facility?

Our team of experts is here to help. Let’s discuss your specific needs and craft a customized solution.